Tredegar Iron Works

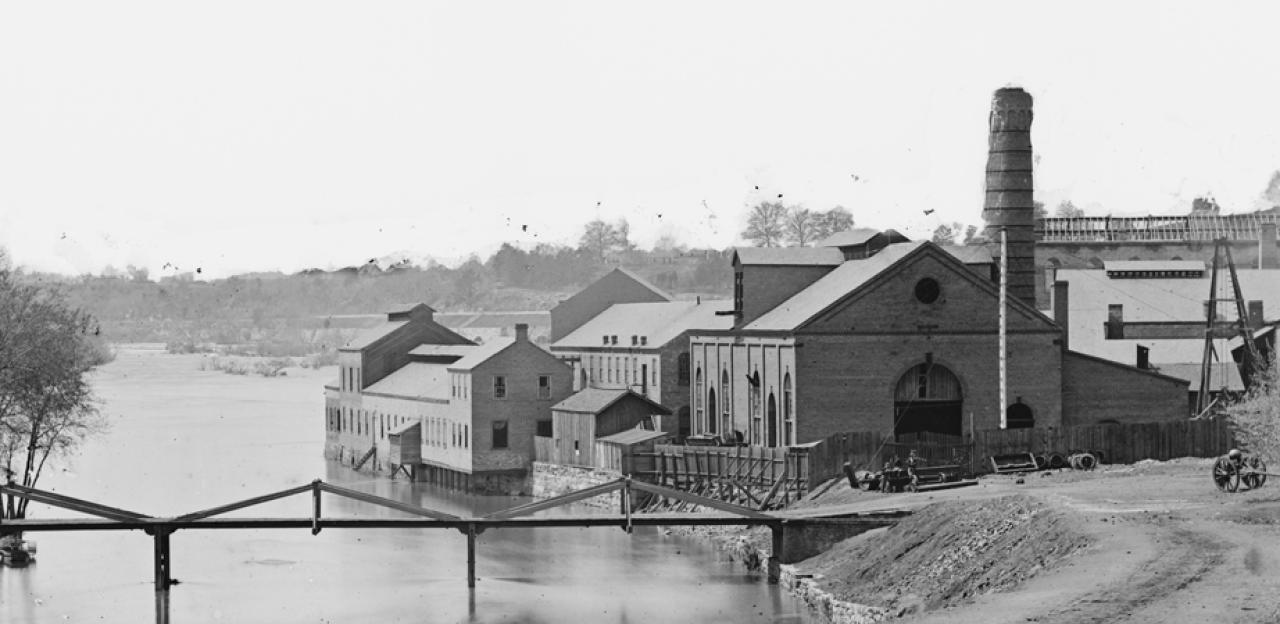

Tredegar Iron Works in Richmond, Virginia, was the main supplier of artillery ordnance during the Civil War. The ironworks origins began in 1837 with the creation of the facility. Tredegar sat alongside the James River, with one building constructed partially on the water. Tredegar greatly expanded when Joseph R. Anderson, a West Point graduate, and engineer, took over the facility. Before Anderson’s involvement, Tredegar produced mostly railroad spikes and small iron items. After Anderson’s involvement, Tredegar began diversifying its workload and began accepting contracts from the federal and state governments to manufacture artillery ordnance.

In 1847, the owners of Tredegar began purchasing slaves to work in the compound. This decision to bring in slave labor dramatically reduced costs and allowed for white workers to be paid more. Many of the workers in the facility before the introduction of slave labor were primarily foreign-born immigrants from Ireland, Wales, Scotland, and Germany. There were few native-born Americans working in the facility. However, by 1861, Tredegar became the largest employer in Richmond as well as the largest ironworks facility in the South. Throughout the life of Tredegar, many families worked at the ironworks for generations, such as the Osterbind Family, as well as children and grand-children of Joseph Anderson.

At the onset of the Civil War, Tredegar Iron Works was one of the primary reasons that the capital of the Confederacy was moved from Montgomery, Alabama, to Richmond, Virginia. Tredegar’s industrial capacity to produce artillery pieces at a rapid pace proved useful to the Confederate war machine. Tredegar was the only foundry in the South to be able to produce artillery ordnance. Due to Joseph R. Anderson’s call to diversify their production efforts in the 1840s and 50s, Tredegar had bought some artillery casts from northern foundries which gave it an edge over other southern foundries that did not have the ability to produce cannons. Tredegar was also used to help in the production of railroad spikes that were used to expand the southern railways to improve the South's infrastructure when the South had fewer railroads than in the North.

Over the course of the war, Tredegar produced more than 1,100 cannons. Tredegar manufactured the iron plating that went on the first Confederate ironclad ship, the CSS Virginia. Tredegar also produced steam trains and railroad spikes during the war. As the war went on, slave labor was heavily relied upon due to the conscription of white men into the Confederate army. By March of 1865, Tredegar had stopped the production of cannons. At the fall of Richmond in April of 1865, Tredegar was placed under the protection of Union soldiers. This protection saved the ironworks from harm by the fleeing Confederate forces and escaped the flames from the burning.

After the war, Tredegar had to purchase new equipment and repair a few parts of the facility and got back to operation by the end of 1865. Tredegar began producing railroad spikes and steam trains again after a boom in railroad supplies from 1865-1873 due to the Transcontinental Railroad’s creation. In 1898, Tredegar was contracted by the federal government to create munitions and small arms for the American war effort for the Spanish American War. By 1900, Tredegar’s facility had grown from a few buildings to encompassing about 23 acres of land along the James River. From 1900 until 1957, Tredegar continued to produce iron materials for railroads until the Albemarle Paper Company purchased the buildings in 1957.

Tredegar’s legacy as a major industrial complex extends through America’s modern history. Tredegar set a precedent in the southern states that Tredegar was the model of southern industrial output. While in the later years of the foundry’s life, Tredegar failed to adapt to the modern need for steel. However, in its heyday, Tredegar provided Richmond, the Confederacy, and the country with iron tools, cannons, and railroad supplies that shaped the Richmond area.